T-Slot nuts and clamping studs play a vital role in ensuring precise and secure workholding solutions in various industries. To maximize their lifespan and maintain their efficiency, it’s crucial to follow proper maintenance and usage practices. In this blog, we’ll provide you with essential tips to help you get the most out of your T-Slot nuts and clamping studs.

1. Choose the Right T-Nut: Select the appropriate T-nut according to the DIN/IS Standard recommended for your T-Slot size. Using the correct T-nut ensures optimal compatibility and functionality.

2. Avoid Tampering with Bench Grinding: Refrain from tampering with T-Slot nuts or clamping studs using bench grinding. This could lead to irregularities, affecting the performance and integrity of these components.

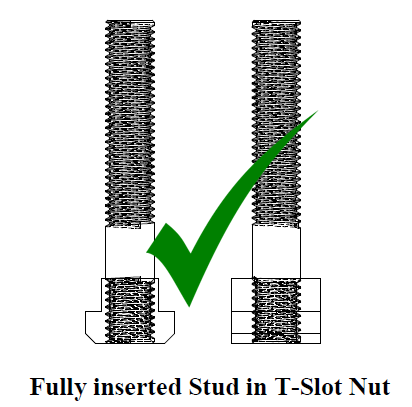

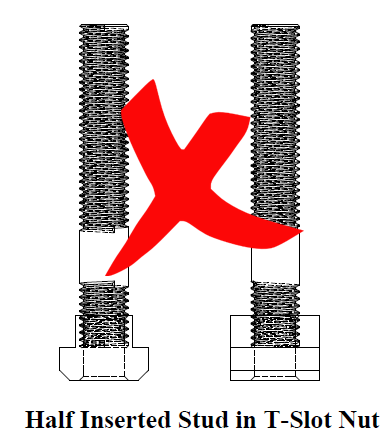

3. Proper Insertion of Stud into T-Nut: Ensure the stud is fully inserted into the T-nut to prevent cracking or damaging the thread within the T-nut. This proper fitment is essential for maintaining the structural integrity of the components.

4. Recognize Signs of Stress: Be vigilant for signs of elongation or an increase in thread pitch on both the stud and T-nut. These signs may indicate that the components are under stress and may need replacement.

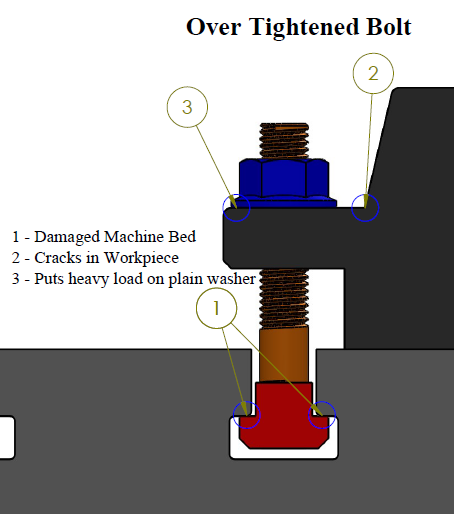

5. Follow Recommended Tightening Torque: Adhere to the recommended tightening torque specified for T-Slot nuts and clamping studs. Over-tightening can have adverse effects on machine bed T-Slots, workpieces, nuts, and washers, leading to potential damage.

6. Avoid Over Tightening: Exercise caution to prevent over-tightening. Overly excessive force can result in unnecessary strain on the components, leading to premature wear and tear.

7. Lubrication for Enhanced Clamping: Regular lubrication aids in achieving effective clamping by reducing the frictional coefficient. This, in turn, extends the thread life of T-Slot nuts and clamping studs.

By adhering to these maintenance and usage guidelines, you can significantly increase the longevity and efficiency of your T-Slot nuts and clamping studs. Remember, these components are crucial for achieving accurate and secure workholding solutions. Following these tips not only ensures optimal performance but also contributes to cost-effective and seamless operations.

At Reach Tools, we prioritize the durability and performance of our products. Our T-Slot nuts and clamping studs are designed to meet rigorous standards, and proper maintenance will only enhance their reliability and longevity. Feel free to reach out to us for any queries or assistance regarding the maintenance and usage of these components.